Rotary Engines In Aircraft - Normally, Wankel engines are limited to a rotor speed of 3,000 revolutions per minute (rpm) due to excessive bending of the crankshaft caused by the centrifugal forces of the rotor. The Szorenyi engine is not limited in this respect, as it used a horizontal rotor.

The Wankel rotary engine was the preferred choice for many owners and operators of small glider-powered aircraft. Compared to conventional piston engines, Wankel cycle engines are smaller, lighter and have a higher power-to-weight ratio. They are virtually vibration free, can't hit or knock, and have few moving (break) parts. At this stage, it is difficult to improve the Wankel design; That is, unless you consider changing the shape of the rotor… to a different shape.

Rotary Engines In Aircraft

A new rotary engine configuration - the Szorenyi rotary engine - has been developed by the Melbourne-based Rotary Engine Development Agency (REDA). Although the stator, or stationary part of a Szorenyi motor is similar to a Wankel motor, the geometric shape of the motor's rotor is a rotor that is deformed as it rotates within the stator contour. Szorenyi engine cycle

The Rotary Engine

This geometry translates to a rotary engine with four combustion chambers, as opposed to the traditional three-cycle Wankel. Each revolution of the crankshaft produces one revolution of the rotor and a complete revolution of the engine in all four chambers: or four strokes of power. In contrast, the Wankel engine produces one power stroke for each revolution of the crankshaft.

A typical Wankel cycle engine uses a three-way rotor to create cavities within the stator for a continuous cycle of intake, compression, ignition and exhaust. Point A marks one of the three tips of the rotor, point B marks the eccentric shaft, and the white part is the lobe of the eccentric shaft. (Image source: Y tambe)

According to REDA, each four-stroke Szorenyi cycle module is equivalent to an eight-cylinder reciprocating or reciprocating piston engine.

The Szorenyi engine is also more optimized for the multi-rotor configuration due to the Wankel's use of rotating side ports rather than the Wankel engine's use of complex side ports. The ability to easily configure multi-rotor, four-stroke engines can result in rotary engines that produce the same power as 8-, 16-, or 24-cylinder engines. In addition, the development of standardized modules can reduce the production and maintenance costs of the life cycle. Free Speed Normally, Wankel engines are limited to a rotor speed of 3000 revolutions per minute (rpm) due to the bending of the crankshaft caused by the centrifugal forces of the rotor. The Szorenyi engine is not limited in this respect, as it used a horizontal rotor.

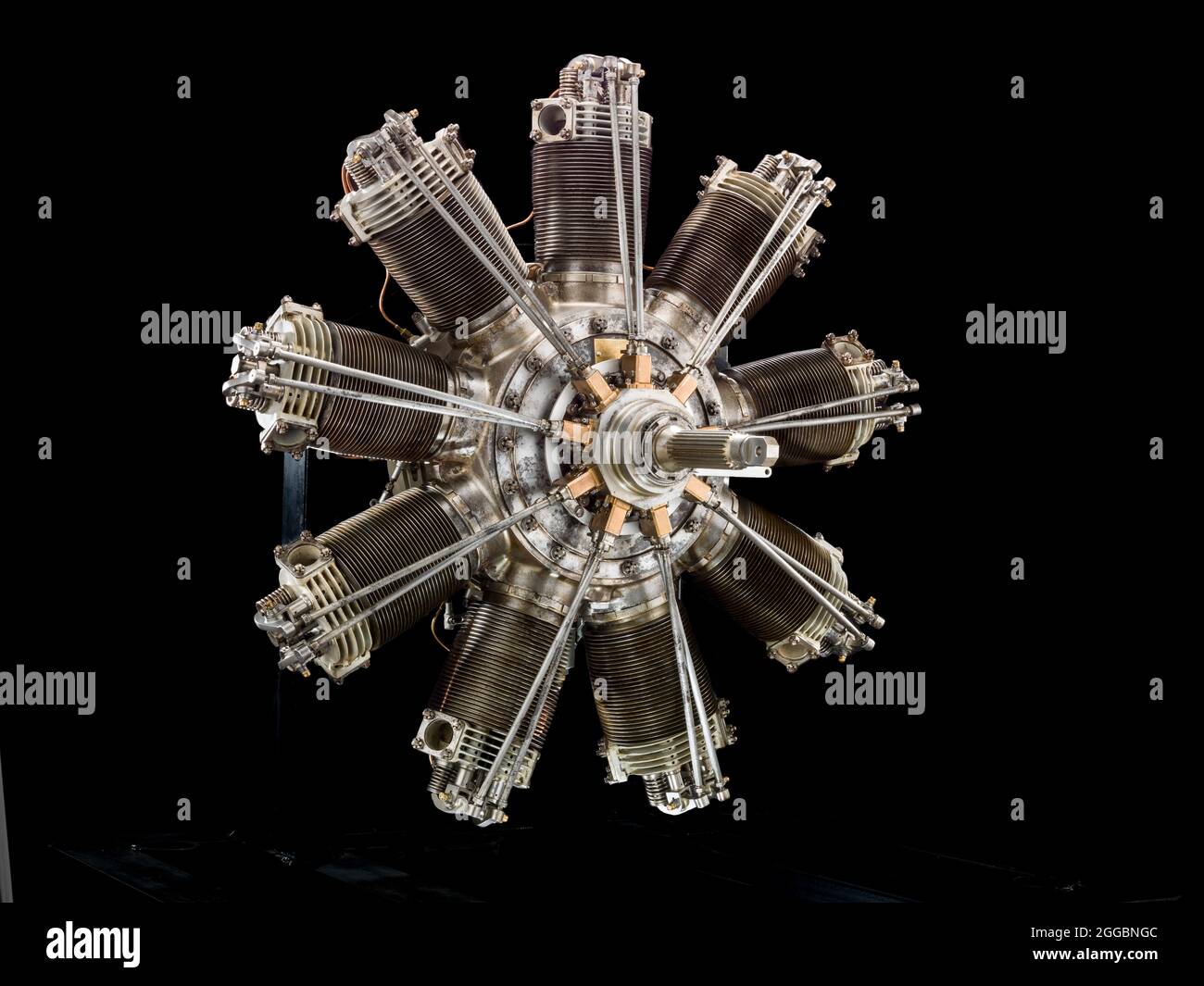

Bentley B.r.2 Rotary Engine

The higher possible torque limits mean that the Szorenyi engine has a higher power density than the Wankel engine, which can translate into greater flight range, endurance and payload capacity. In addition, the Szorenyi engine has more room for internal rotor cooling and does not require a reduction mechanism in aircraft and unmanned aerial vehicles (UAVs) with large propellers.

According to the paper, the Szorenyi engine can be made using gasoline, aviation gasoline (avgas), butane, or hydrogen (since the inlet and exhaust ports are well separated).

REDA also noted that if the pre-compression phase were to be introduced, the engine could run on diesel fuel - in keeping with the US military's "one fuel" concept and possibly considering the engine for military use.

An abridged version of Szorenyi's four-cam rotary engine development and other technical papers on small aircraft and UAV engines are available in the latest International book.

Gnome 9b 2 Engine History

This book covers several UAV propulsion technologies, such as traditional heavy-fuel engines, hybrid-electric architectures, hydrogen-powered distributed fans, the aforementioned Szorenyi rotary engine, and experimental plasma impregnation - or discharge for the dielectric barrier.

William Kucinski Content Editor International, Aerospace Products Group in Warrendale, PA. Before that, he worked as a writer at NASA's Security Center in Cleveland, OH, and was responsible for writing system failure studies for the agency. His interests include everything related to aviation, past and present military aircraft and engine technology. Definition of a consensus engine. Reality Fully functional experimental aircraft Wankel rotary devices today are the work of two companies: American Rotary Engine and Auto PSRU's (see listing below). The former builds the engine and the latter builds the propeller gearboxes.

The American rotary engine is an aerodynamic sidebar from Atkins Rotary, a neck-deep hot rod shop that mods and supports Mazda Wankels for racers. He makes pop-up parts and adapters for just about anything that moves and fits. As Mazda parts continue to be manufactured, the American rotor engine has been working harder to produce replacements, including some nifty bits like its own, redesigned rotor housing. Water pump covers and housings.

For aviation, American Rotary Engine considers the Mazda 13B engine. And while American jokes that all customers want is a "500-horsepower engine that weighs 30 pounds," it offers 200-horsepower, turbocharged packages. A distinct American Aviation development is a spring-loaded pop-up valve set at 4 pounds to prevent over-inflating after a descent or rollover.

Gnome N 9 > National Museum Of The United States Air Force™ > Display

More power from Chevy V-8s is a customer request at AutoPSRU. The LS-3 engine is mated to their SD550 gear reduction unit, which has a center clutch for reduced starting and other shock loads.

Engine distribution and packaging specialist Auto PSRU loves its naturally aspirated and turbocharged Mazda 13B engines from American Rotary (see previous listing). Auto PSRU's long-term offering is a 200-hp gun for the RV-7. Interestingly, after a six-year drought, interest in Wankels has picked up again in 2020, especially in the more powerful 13B variants.

Dan Parker was another fan trying to make his mark in space with some crazy, amazing project. He then met Facet Opel, the current length record holder, and the race began. Since then, he has been working on his plane full-time in hopes of breaking the existing record, and along the way he has demonstrated creativity and strong construction and design practices.

It is this wing that gives the latest Bob Burrows design a faster ride and slower speed than the equivalent LSA. By Chuck Burt.

The Resurrection Of Ww1 Rotary Engines

Ads-b airventure avionics technology building dar design technology dynon eaa efis efis electric motors electronics faa fly-in fuel fwf garmin history home builder humor tool building lsa lycoming maintain ownership test events product propellers racing racing rules reno replica safety shop tip sonex subsonex sun ' zenith video fun tools

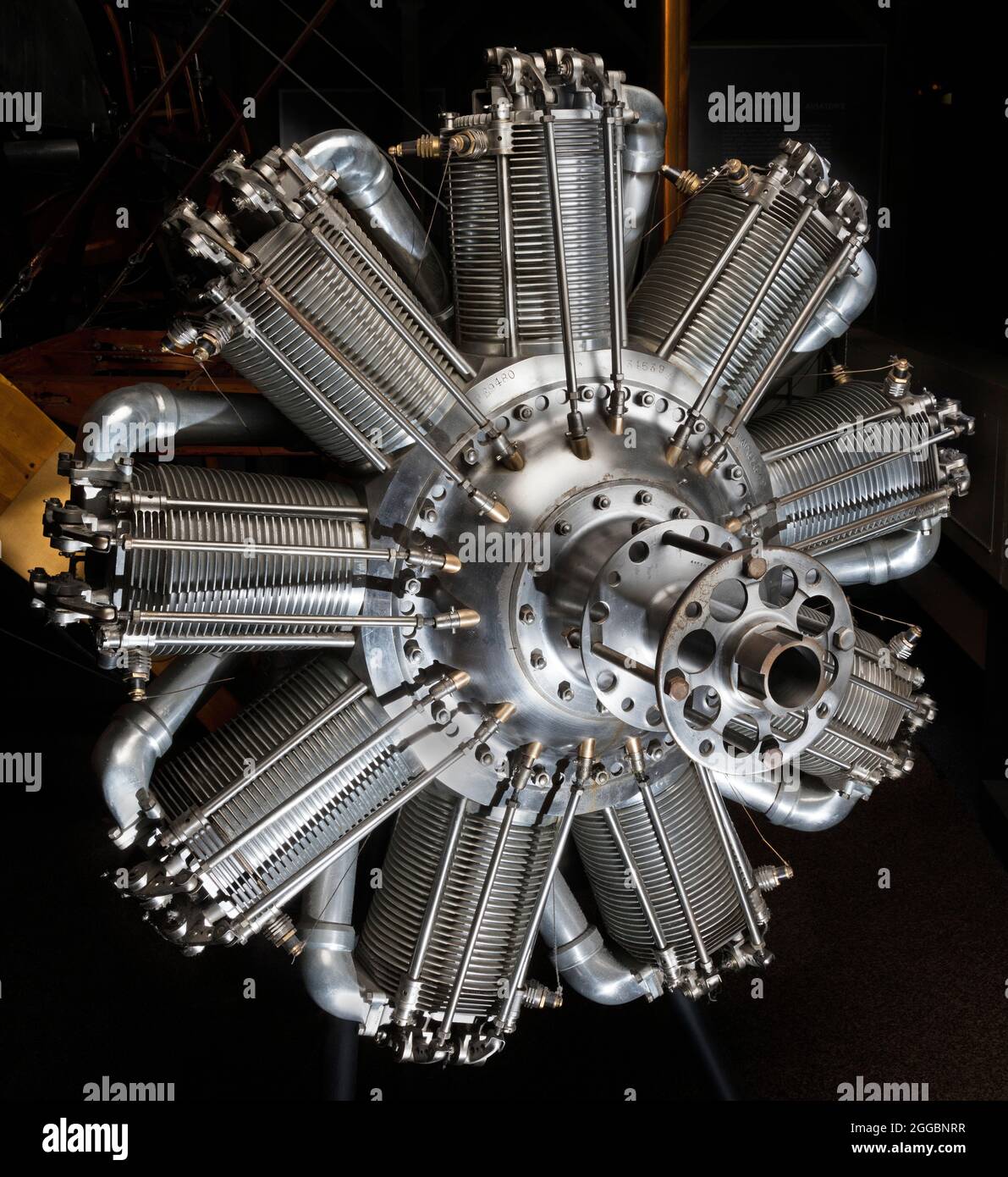

© 2023. All rights reserved worldwide. And the logo is protected by international copyright law. The French Le Rhône rotary engine is one of the most important designs of early aviation engineering and provided air power for the Allies during World War I. This air-cooled engine produced better power. weight ratio than liquid cooled engines.

Early aircraft engines suffered greatly from overheating. What makes the Le Rhône an engineering marvel is the entire engine block that is rotated by a propeller around a fixed crane. The rotary engine design has largely solved the heat problem. Interestingly, the torque created by the rotating engine made the plane want to "move" along with the engine, making the journey difficult and dangerous. Learn more.

An hour into the flight, Le Rhône's engine sprayed two gallons of castor oil into the air. When the engine revved and the cockpit was opened, the pilots found themselves covered in oil and often fell ill from the sedative effects of the castor oil.

Pierre Clerget Was Inspired By The Gnome To Produce A Supposedly Improved Rotary Engine In 1911. It Was A 7 Cylinder, 11.88 Liter (725 Cu In) Engine Rated At 60 Kw (80 Hp)

Pilots wore goggles and white scarves to protect their faces. A silk scarf protected their necks from chafing as they scanned the skies for enemy planes, and served as a cloth to clean their glasses. why white White means clean and they didn't want to wipe the glasses and face with a greasy cloth!

Made in France by Gnome et Rhône, approximately 25,000 Le Rhône rotary engines saw service during the First World War. This engine dates from around 1918 and is on display in the First World War Museum Gallery. Hanging above is the Sopwith Pup, one of the aircraft with this type of engine. Built with safety in mind, the museum's Sopwith Pup (replica) does not have a rotary engine as it would have in its original configuration.

Video Credit: WWILe Rhône Rotary Engine Launches Uploaded to YouTube by the National Museum of the United States Air Force 2014 Rated at 100 hp, the CAMS Gnome rotary engine is nearly 13 liters and produces 125 hp at 1125 rpm at 578lb and - ft. of torque. Selling for $62,000 FOB Blenheim, New Zealand.

If you've had the rare chance to see a World War I aircraft up close, it will be clear why so many early aircraft have been meticulously recreated. Products of an era of low-wage labor and easy access to skills and techniques long lost to history, building a true continuation aircraft proved to be a daunting task for even the most dedicated and well-funded hobbyist.

Rotary Aircraft Engine Editorial Stock Image. Image Of Yorkshire

But now, perhaps especially, Kip Lankenau of Dallas, Texas, is taking on this serious task through his Kip Aero aircraft business. A

Aircraft rotary engines, aircraft engines for sale, rotary engines for aircraft, electric aircraft engines, continental aircraft engines, cars with rotary engines, rotary engines mazda, rotary engines for experimental aircraft, general electric aircraft engines, wankel rotary aircraft engines, lycoming aircraft engines, rebuilt aircraft engines

Post A Comment:

0 comments so far,add yours